What Is 3D Printing? Discover the Essentials of 3D Printing and Its Applications

What Is 3D Printing? Discover the Essentials of 3D Printing and Its Applications

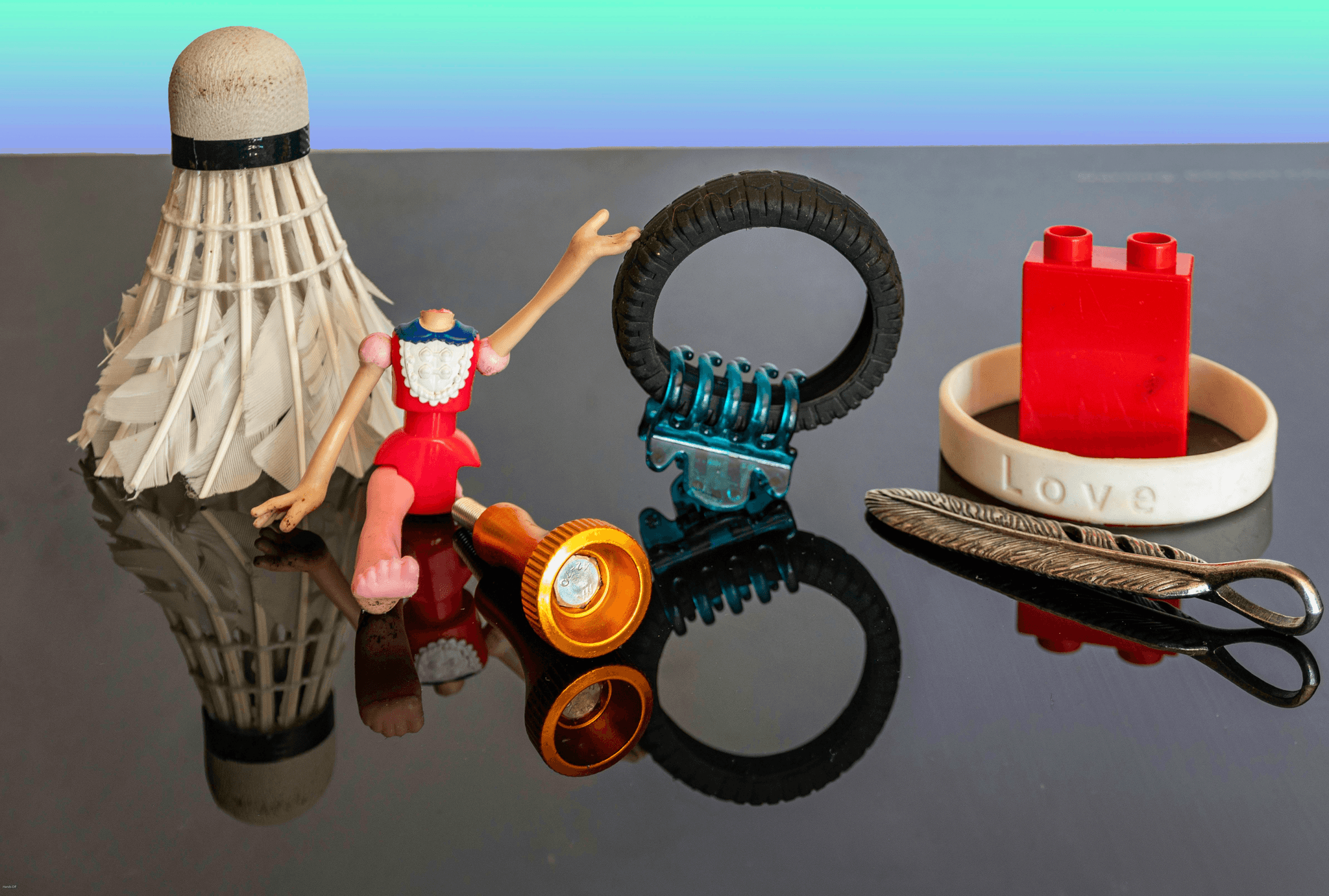

3D printing has revolutionized the way we manufacture products and create prototypes. This cutting-edge technology allows for creating three-dimensional objects from digital files, making it a game-changer in various industries. From aerospace to healthcare, 3D printing is reshaping how we approach design and production.

I mean, it's crazy how 3D printing is changing the game, right? Like, you can literally just print out a physical object from a digital file. It's not just for making cool prototypes either - industries like aerospace and healthcare are using it to actually produce real products. And who knows what other industries will start using it in the future? It's pretty exciting stuff.

Understanding the 3D Printing Basics

At its core, 3D printing involves the layer-by-layer creation of physical objects based on a digital model. This process, also known as additive manufacturing, eliminates many traditional manufacturing constraints and allows for intricate designs that were previously impossible to produce.

Exploring the Different Types of 3D Printing

There are several types of 3D printing technologies, each with unique processes and applications. From fused fluid fabrication (FFF) to stereolithography (SLA) and selective laser sintering (SLS), understanding these different methods is crucial to harnessing the full potential of this innovative technology.

Applications of 3D Printing in Various Industries

The impact of 3D printing extends across numerous sectors, including aerospace, healthcare, automotive, and more. From rapid prototyping to custom medical devices and even architectural models, 3D printing's versatility makes it an indispensable tool in modern manufacturing and design processes.

What Is 3D Printing?

Art Player Template from Strikingly

3D printing is an innovative manufacturing process involving three-dimensional objects by layering materials based on a digital model. This cutting-edge technology allows for producing complex and customized designs with precision and efficiency, revolutionizing traditional manufacturing methods.

Definition and Concept of 3D Printing

3D printing, also known as additive manufacturing, revolves around the layer-by-layer construction of objects using various materials such as plastics, metals, ceramics, and more. This process eliminates the need for molds or tooling, making it a cost-effective and flexible solution for creating prototypes, finished products, and parts on demand.

Historical Background of 3D Printing

The history of 3D printing dates back to the early 1980s when its initial concepts were developed. Over the years, advancements in technology have propelled the evolution of 3D printing from rapid prototyping to its current widespread applications across diverse industries such as aerospace, healthcare, automotive, and consumer goods.

Key Components and Processes Involved in 3D Printing

Key components involved in 3D printing include a digital design file created using computer-aided design (CAD) software, a 3D printer equipped with precise nozzles or lasers for material deposition or solidification, and suitable materials compatible with the specific type of 3D printing technology. The processes may vary based on the type of 3D printing method employed but generally involve layering materials to build up the final object.

Types of 3D Printing

Regarding 3D printing, several types of technologies are commonly used. Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is one of the most popular types of 3D printing. It involves using a thermoplastic filament that is heated and extruded through a nozzle layer by layer to create the final object. Stereolithography (SLA) is another type of 3D printing that uses photopolymerization, where a UV laser cures a liquid resin to create solid layers. Selective Laser Sintering (SLS) uses a high-powered laser to convert powdered material into a solid structure, typically nylon or metal.

1. Fused Filament Fabrication (FFF)

Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is one of the most widely used types of 3D printing technology. It works by melting and extruding thermoplastic filament through a heated nozzle onto a build platform, layer by layer, to create the desired object. This type of 3D printing is known for its affordability and accessibility, making it popular among hobbyists and small businesses looking to prototype their designs before mass production.

2. Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing process that uses photopolymerization to create solid objects from liquid resin. The process involves using an ultraviolet laser to trace out each layer of the object on the surface of the liquid resin, causing it to harden and form the desired shape. SLA technology is known for its high detail and accuracy, making it suitable for creating intricate prototypes and models in industries such as jewelry design, dentistry, and engineering.

3. Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an additive manufacturing technique using a high-powered laser to sinter powdered material into a solid structure. This method creates complex geometries with high strength and durability, making it ideal for producing functional parts in the aerospace, automotive, and healthcare industries. SLS can work with various materials, including nylon and metal powders like aluminum or titanium, enabling a wide range of applications in different industries.

3D Printing Basics

Hayes Gallery Template from Strikingly

Various materials can be used for 3D printing, including plastics, metals, ceramics, and even food ingredients. These materials are carefully selected based on the specific requirements of the intended 3D-printed object. For instance, plastic filaments are commonly used for creating prototypes and consumer products due to their cost-effectiveness and versatility.

When it comes to 3D printing with metals, materials like stainless steel, titanium, and aluminum are often used for creating durable and high-quality parts for industries such as aerospace and automotive. These metal 3D-printed parts offer excellent strength and heat resistance, making them suitable for demanding applications. On the other hand, ceramics are chosen for their ability to withstand high temperatures and corrosion, making them ideal for creating components used in harsh environments like chemical processing plants or medical implants.

Materials Used in 3D Printing

In addition to plastics, metals like titanium and aluminum are utilized in industrial-grade 3D printers for applications in the aerospace and automotive industries. Meanwhile, bioinks made from living cells are employed in medical 3D printing to create tissues and organs for transplantation. Each material has unique properties that make it suitable for different types of 3D printing projects.

Advantages and Limitations of 3D Printing

The advantages of 3D printing include rapid prototyping, customization capabilities, reduced material wastage, and increased design freedom. However, limitations such as slow production speed for large-scale manufacturing and limited material options for specific applications still exist. As technology advances, these limitations are gradually addressed through ongoing research and development efforts.

Future Trends and Developments in 3D Printing Technology

The future of 3D printing is promising as advancements continue to push the boundaries of what is possible with this technology. Some exciting trends include using sustainable materials for eco-friendly production, integrating artificial intelligence for automated design optimization, and exploring new frontiers such as bioprinting living tissues and organs.

Applications of 3D Printing

Strikingly Website on a Laptop

The applications of 3D printing are vast and varied, with each industry finding unique ways to utilize this technology. In the aerospace and defense industry, 3D printing creates complex parts and components for aircraft and military equipment. It allows rapid prototyping and customization, leading to cost savings and improved performance.

In the medical field, 3D printing has revolutionized the production of prosthetics, implants, and even organs. This technology enables healthcare professionals to create custom solutions for patients, improving comfort and functionality. Additionally, 3D printing allows for the creation of anatomical models for surgical planning and training, ultimately leading to better patient outcomes.

Aerospace and Defense Industry

In the aerospace and defense industry, 3D printing revolutionizes how aircraft and military equipment are designed and manufactured. Companies use various types of 3D printing, such as selective laser sintering (SLS), to create lightweight yet durable parts that were previously impossible to produce using traditional methods. This has led to increased efficiency in production processes and enhanced performance of aerospace components.

Healthcare and Medical Sector

In the healthcare sector, 3D printing has been a game-changer, allowing for the creation of patient-specific implants, prosthetics, and organ models for pre-surgical planning. Types of 3D printing like fused filament fabrication (FFF) are used to produce custom medical devices with intricate designs that perfectly fit individual patients. This has significantly improved patient outcomes while reducing costs associated with traditional manufacturing methods.

Automotive and Manufacturing Sector

The automotive industry has also embraced 3D printing technology to streamline production processes, reduce material waste, and create complex parts that enhance vehicle performance. Additive manufacturing techniques like stereolithography (SLA) produce lightweight yet solid components for cars, trucks, and motorcycles. This has led to greater design flexibility in creating innovative automotive solutions while reducing environmental impact through sustainable manufacturing practices.

Exploring these applications across different industries reveals that 3D printing is transforming traditional manufacturing processes through its versatility and efficiency.

Strikingly Features Related to 3D Printing

Strikingly Landing Page

When it comes to showcasing your 3D printing work, creating a portfolio website is essential. This platform allows you to display your projects, highlight your skills, and attract potential clients or employers. With the right design and content, a 3D printing portfolio website can demonstrate your expertise and creativity in this field.

Showcasing your projects is a great way to make an impact in the 3D printing industry. Whether it's a prototype, a custom design, or a complex model, displaying your work can help you gain recognition and credibility. By sharing detailed images and descriptions of your projects, you can effectively communicate the value of your creations to others.

Engaging with others in the 3D printing community is crucial for professional growth. Creating a blog that discusses industry trends, project updates, and personal insights can help you connect with like-minded individuals. By using visually appealing templates and sharing valuable content, you can establish yourself as a thought leader in the world of 3D printing.

Unveiling the Future: 3D Printing with Strikingly

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects from a digital file. Unlike traditional manufacturing methods, 3D printing builds objects layer by layer, allowing for greater customization and flexibility.

Strikingly's Role in the 3D Printing Industry

Strikingly, with its user-friendly platform and powerful features, can play a significant role in the 3D printing industry by:

- Showcasing 3D Printed Products. Create a visually appealing website to showcase your 3D-printed products or services. Strikingly's templates and design tools make creating a professional online presence easy.

- Educating Your Audience. Provide informative content about 3D printing, its applications, and its benefits. Strikingly's blogging platform allows you to create and publish blog posts.

- Building Community. Connect with other 3D printing enthusiasts and professionals through Strikingly's community features.

- E-commerce Integration. Sell your 3D printed products or services directly through your Strikingly website. Strikingly's e-commerce features make it easy to set up an online store.

- Customer Engagement. Use Strikingly's live chat and contact form features to engage with your customers and provide excellent support.

- Lead Generation. Capture leads and build your email list using Strikingly's lead capture forms.

- SEO Optimization. Improve your website's visibility in search engine results pages (SERPs) to attract organic traffic. Strikingly's SEO tools can help you optimize your content.

- Analytics. Track your website's performance and measure key metrics like traffic, engagement, and conversions. Strikingly's analytics tools provide valuable insights.

- Mobile Optimization. To cater to the growing number of mobile users, ensure your website is optimized for mobile devices. Strikingly's templates are automatically designed for mobile responsiveness.

- Scalability. Strikingly's platform can scale as your business grows to accommodate your expanding needs.

By leveraging Strikingly's platform and effectively utilizing its features, you can create a successful online presence for your 3D printing business, educate your audience, and drive growth in this exciting and innovative industry. Remember, a well-designed and informative website is essential for establishing your brand's authority in the competitive world of 3D printing.

Harness the Power of 3D Printing Technology

Strikingly Website on Mobile

3D printing has revolutionized the manufacturing industry by enabling rapid prototyping and customization of products. Its ability to create complex shapes and structures has unlocked new possibilities in various sectors, from healthcare to aerospace.

Embracing Innovation in 3D Printing

As the technology continues to evolve, businesses and individuals must embrace innovation in 3D printing. From experimenting with new materials to exploring advanced printing techniques, staying updated with the latest trends is essential for harnessing the full potential of 3D printing.

Exploring the Endless Possibilities of 3D Printing

The future of 3D printing holds endless possibilities, from creating sustainable and eco-friendly products to pushing the boundaries of design and creativity. As this technology becomes more accessible, it will empower individuals and industries to explore new horizons and redefine what is possible in manufacturing.