The Truth About Supply Chain Shortages In 2023

The Truth About Supply Chain Shortages In 2023

Supply chain shortages have become a significant challenge for businesses across various industries. These shortages occur when there is an imbalance between supply and demand, resulting in a lack of essential resources or products. Supply chain shortages can be far-reaching, affecting individual businesses and the economy.

The Impact of Supply Chain Shortages

When supply chain shortages occur, businesses may need help meeting customer demands and promptly fulfilling orders. This can lead to dissatisfied customers, lost sales opportunities, and damage to a company's reputation. Supply chain shortages can also disrupt production processes, leading to delays and increased costs.

Furthermore, supply chain shortages can have ripple effects on other industries and sectors. For instance, if a manufacturing company experiences a shortage of raw materials, it may be unable to produce goods, causing retailers to suffer from empty shelves and lost sales. This domino effect can disrupt the entire economy, reducing consumer spending and economic downturns. Ultimately, supply chain shortages highlight the interconnectedness of businesses and emphasize the importance of robust and resilient supply chains in today's globalized World.

Understanding Supply Chain Shortages

To effectively manage supply chain shortages, it is crucial to understand their root causes and implications. Supply chain shortages can arise due to various factors, such as disruptions in transportation networks, natural disasters, labor strikes, or unexpected increases in demand. By understanding these factors, businesses can better anticipate and mitigate the risk of supply chain shortages.

To effectively manage supply chain shortages, businesses must also consider the potential long-term implications. A shortage in the supply chain can lead to decreased customer satisfaction, damaged reputation, and, ultimately, loss of market share. It is crucial for companies to proactively address these shortages by diversifying suppliers, implementing contingency plans, and investing in technology that allows for real-time monitoring and adjustment. By doing so, businesses can minimize the immediate impact of shortages, build resilience, and maintain a competitive edge in an unpredictable market landscape.

Critical Strategies for Managing Supply Chain Shortages

Managing supply chain shortages requires proactive planning and strategic decision-making. Businesses must implement key strategies focusing on enhancing supplier relationships, optimizing inventory management techniques, and adopting agile supply chain strategies. These approaches can minimize the impact of supply chain shortages and ensure business continuity.

In addition to implementing key strategies, businesses should consider diversifying their supplier base as a proactive measure against supply chain shortages. Relying on a single supplier can leave businesses vulnerable to disruptions, such as natural disasters or unexpected market fluctuations. By cultivating relationships with multiple suppliers, companies can reduce the risk of supply chain shortage issues and maintain a steady flow of goods. Furthermore, regularly evaluating and reassessing supplier performance can help identify potential supply chain shortage issues early on and allow businesses to make informed decisions regarding their supply chain partnerships. Being proactive in diversifying suppliers safeguards against shortages and promotes resilience in the face of unforeseen challenges.

The Current State of Supply Chain Shortages

Image taken from Bahia Blanca

Supply chain shortages have become a pressing issue in today's global economy. Understanding the causes and factors contributing to these shortages is crucial for effectively managing them. The high demand and limited supply dynamics further exacerbate this challenge, resulting in significant ripple effects across various industries.

Factors Contributing to Supply Chain Shortages

Several reasons and factors contribute to supply chain shortages. One primary factor is disruptions in the production process, such as natural disasters, labor strikes, or equipment failures. These events can lead to delays or even complete shutdowns of manufacturing facilities, resulting in a shortage of goods.

Another contributing factor is inadequate inventory management practices. Forecasting, accurate demand planning, and sufficient safety stock levels can all lead to supply chain shortages. With proper inventory management strategies, businesses can meet customer demands when unexpected fluctuations occur.

Additionally, global market conditions and geopolitical factors can play a significant role in creating supply chain shortages. Tariffs, trade disputes, or political unrest can disrupt the flow of goods across borders and impact the availability of raw materials or finished products.

High Demand and Limited Supply: A Common Challenge

The imbalance between high demand and limited supply is a common challenge businesses face across industries. Increasing consumer expectations and rapid technological advancements have led to heightened demand for innovative products at faster speeds.

Simultaneously, supply chains are often stretched thin due to various constraints, such as capacity limitations or transportation bottlenecks. This creates a situation where businesses need more supply capacity to meet customer demands.

The Ripple Effect: How Supply Chain Shortages Impact Various Industries

Supply chain shortages have far-reaching consequences that extend beyond individual companies. When one link in the supply chain experiences a shortage, it affects all downstream partners who rely on their products or services.

For example, if an automotive manufacturer faces a shortage of semiconductors, it can disrupt the production of vehicles. This, in turn, affects suppliers of components, dealerships, and, ultimately, consumers who face delays in purchasing their desired cars.

Similarly, shortages in essential commodities like food or medical supplies can severely affect healthcare providers and consumers. These ripple effects highlight the interconnectedness of supply chains and the need for proactive management to mitigate disruptions.

Understanding the Basics: What is a Supply Chain Shortage?

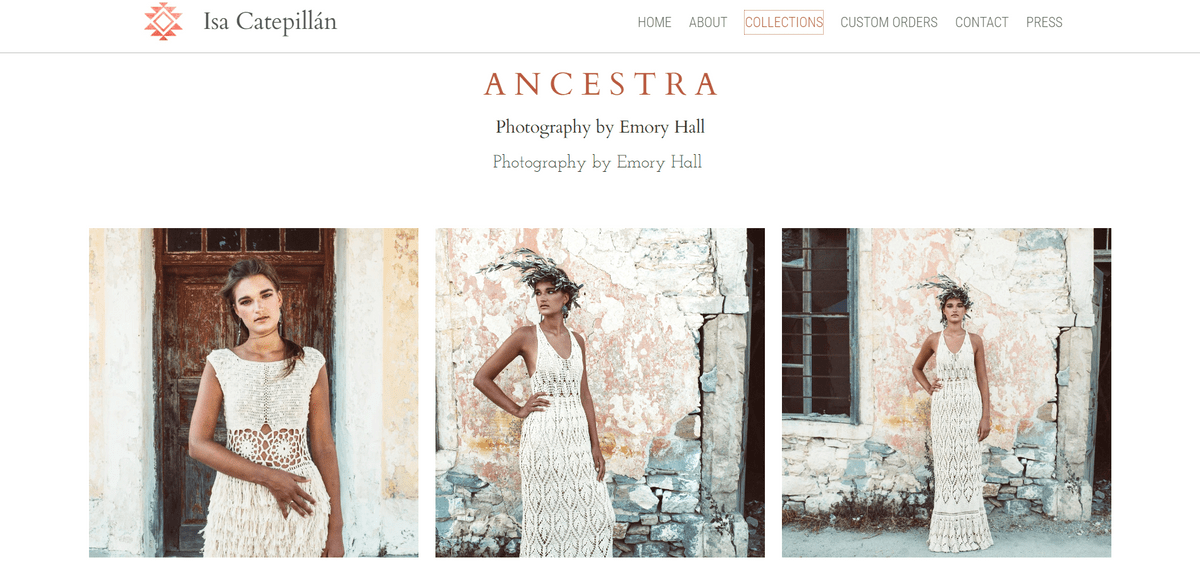

Image taken from Isa Catepillan

Supply chain shortages refer to the situation where there is an insufficient supply of goods or materials to meet the demand. This can occur due to various reasons, such as disruptions in production, transportation delays, or unexpected spikes in demand. The implications of supply chain shortages can be significant, leading to delayed deliveries, increased costs, and customer dissatisfaction.

What is a Supply Chain Shortage

A supply chain shortage occurs when there is an inadequate supply of products or materials to meet customer demand. This can result in delays in fulfilling orders, backorders, or even complete unavailability of certain products. The implications of these shortages can be far-reaching and impact both businesses and consumers.

Supply chain shortages can lead to lost sales opportunities and decreased business revenue. It can also disrupt production schedules and increase operational costs, as companies may have to expedite shipping or find alternative suppliers at higher prices. Moreover, a company's reputation can only be recovered if customers experience consistent product unavailability.

On the consumer side, supply chain shortages can cause frustration and inconvenience. Customers may have to wait longer for their desired products or settle for alternatives that may only partially meet their needs. Additionally, scarcity often increases prices as demand outweighs supply, resulting in higher consumer costs.

The Role of Inventory Management in Avoiding Shortages

Effective inventory management plays a crucial role in avoiding supply chain shortages. By carefully monitoring inventory levels and accurately forecasting demand patterns, businesses can ensure they have sufficient stock to meet customer needs.

Proper inventory management involves balancing carrying excess stock (which ties up capital) and having too little (which leads to shortages). This requires implementing robust inventory tracking systems that provide real-time visibility into stock levels across the entire supply chain.

By leveraging technology such as inventory management software and data analytics tools, businesses can optimize their inventory levels, identify potential shortages in advance, and take proactive measures to address them. This includes establishing reorder points, implementing safety stock, and utilizing just-in-time (JIT) inventory management techniques to minimize the risk of shortages.

The Importance of Effective Demand Planning

Effective demand planning is another critical aspect of managing supply chain shortages. By accurately forecasting customer demand, businesses can align their production and procurement processes to ensure an adequate supply of products.

Demand planning involves analyzing historical sales data, market trends, and customer insights to predict future demand. This enables businesses to adjust their production schedules and inventory levels accordingly.

Moreover, effective demand planning allows companies to anticipate seasonal fluctuations or spikes in demand and proactively adjust their supply chain operations. By collaborating closely with suppliers and sharing accurate demand forecasts, businesses can ensure a timely flow of materials and prevent shortages.

Understanding the basics of supply chain shortages is essential for businesses to manage them effectively. Defining supply chain shortages and recognizing their implications helps companies grasp the significance of addressing these supply chain shortage issues promptly. Inventory management and effective demand planning are vital strategies to help avoid or mitigate supply chain shortages.

Managing Supply Chain Shortages: Best Practices

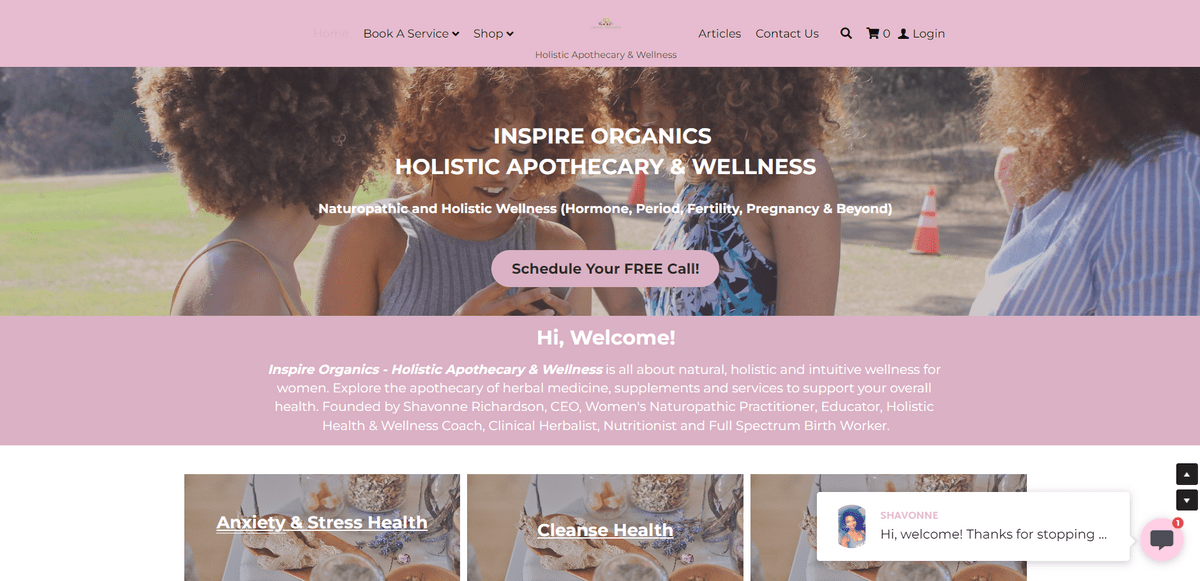

Image taken from Inspire Organics

To effectively manage supply chain shortages, businesses must implement several best practices. These practices include enhancing supplier relationships and collaborations, implementing inventory optimization techniques, and adopting agile supply chain strategies.

1. Enhancing Supplier Relationships and Collaborations

Building solid relationships with suppliers is crucial in managing supply chain shortages. By fostering open communication and collaboration, businesses can work with their suppliers to address potential shortages before they become significant supply chain shortage issues. This can involve sharing demand forecasts, providing visibility into production schedules, and establishing contingency plans.

Additionally, developing long-term partnerships with reliable suppliers can help mitigate the impact of supply chain shortages. By having trusted suppliers who prioritize their relationship with the business, companies can have a better chance of securing necessary resources during times of scarcity.

2. Implementing Inventory Optimization Techniques

Inventory optimization plays a critical role in managing supply chain shortages. By carefully analyzing demand patterns and historical data, businesses can determine optimal inventory levels for different products or components. This allows them to balance having enough stock to meet customer demands while minimizing excess inventory that could tie up capital.

Advanced inventory management systems and tools can also help automate demand forecasting, replenishment planning, and order tracking processes. These technologies enable businesses to make real-time data-driven decisions and respond quickly to demand or supply availability changes.

3. Adopting Agile Supply Chain Strategies

Adopting agile supply chain strategies is essential for effectively managing supply chain shortages. An agile approach involves being flexible and responsive to changes in the market, allowing businesses to adapt their operations when faced with disruptions or uncertainties quickly.

This can be achieved by implementing strategies such as dual sourcing, where companies establish relationships with multiple suppliers for critical components or materials. By diversifying their supplier base, businesses reduce their reliance on a single source due to supplier supply chain shortage issues.

Furthermore, embracing technology and data analytics can enhance agility in supply chain management. By leveraging real-time data and predictive analytics, businesses can identify potential shortages early on, enabling them to take proactive measures to mitigate the impact.

Overcoming Challenges: Strategies for Managing Supply Chain Shortages

Image taken from Natural Shilajit

Supply chain shortages can significantly impact businesses, disrupting operations and causing delays in delivering products to customers. To effectively manage these shortages, companies must implement strategies that address the root causes and minimize their impact. This section will discuss three critical strategies for overcoming supply chain shortages:

- Diversifying supply chain sources.

- Implementing robust risk management strategies.

- Leveraging technology and data analytics to forecast and mitigate shortages.

1. Diversifying Supply Chain Sources

One effective strategy for managing supply chain shortages is to diversify the sources of your supplies. Relying on a single supplier or location can leave you vulnerable to disruptions caused by natural disasters, political instability, or other unforeseen events. By identifying alternative suppliers and expanding your supplier network geographically, you can reduce the supply chain shortage issues.

Diversifying supply chain sources also allows you to negotiate better pricing and terms with multiple suppliers, giving you more flexibility in managing fluctuations in demand. This approach can mitigate the impact of supply chain shortages by providing alternative options when one source experiences disruptions.

2. Implementing Robust Risk Management Strategies

To effectively manage supply chain shortages, it is crucial to have robust risk management strategies in place. This involves identifying potential risks that could lead to shortages and developing contingency plans to address them proactively.

One key aspect of risk management is conducting thorough assessments of suppliers' capabilities and vulnerabilities. By understanding your suppliers' capacity constraints, financial stability, and ability to handle unexpected events, you can assess their risk profile accurately. This information lets you prioritize suppliers based on their reliability and take appropriate measures, such as securing backup suppliers or implementing safety stock levels.

Additionally, establishing clear communication channels with suppliers is essential for managing supply chain shortages effectively. Regularly monitoring supplier performance can help you identify supply chain shortage issues and enable collaborative problem-solving.

3. Leveraging Technology and Data Analytics to Forecast and Mitigate Shortages

In today's digital age, leveraging technology and data analytics is crucial for managing supply chain shortages. Advanced forecasting models can analyze historical data, market trends, and customer demand patterns to predict potential shortages accurately.

Businesses can identify potential bottlenecks in the supply chain early by using real-time data from various sources, such as point-of-sale systems, inventory management software, and supplier portals. This allows for proactive decision-making, such as adjusting production schedules or reallocating inventory to mitigate the impact of shortages.

Furthermore, artificial intelligence and machine learning can help optimize inventory levels by analyzing demand patterns and automatically triggering replenishment orders when stock levels reach predefined thresholds. This reduces the risk of stockouts while minimizing excess inventory that ties up capital.

By leveraging technology and data analytics, businesses can gain valuable insights into their supply chains' dynamics, enabling them to make informed decisions that mitigate the impact of supply chain shortages.

Working With Strikingly For Your Supply Chain Journey

Image taken from The Peacock

Creating a website with Strikingly can be a valuable tool for efficiently managing your supply chain for several reasons. Strikingly is a user-friendly website builder known for its simplicity, versatility, and features tailored to help businesses establish an online presence. Here's why you should consider using Strikingly to manage your supply chain:

- Professional Online Presence. A well-designed website on Strikingly conveys professionalism and trustworthiness to potential partners, suppliers, and customers. This can be crucial in the supply chain management industry, where credibility is essential.

- Easy to Use. Strikingly is known for its intuitive drag-and-drop website builder. You don't need extensive technical skills to create and manage your website, which is a significant advantage for busy supply chain professionals.

- Templates for Your Needs. Strikingly offers a variety of customizable templates, some specifically designed for businesses in the logistics and supply chain sectors. These templates can help you quickly set up your website with the appropriate structure and design.

- Responsive Design. Strikingly websites are automatically optimized for mobile devices. Since supply chain management often involves on-the-go activities, ensuring your website is accessible from smartphones and tablets is crucial.

- E-commerce Features. If your supply chain management business involves selling products or services online, Strikingly provides e-commerce capabilities. You can easily list your products, set up a shopping cart, and facilitate online transactions through your website.

- Integrated Contact Forms. Strikingly allows you to create custom contact forms that make it easy for suppliers, clients, or partners to contact you. This can be especially useful for inquiries, quotes, or collaboration requests.

- SEO-Friendly: Strikingly websites are SEO-friendly, making it easier for your site to rank in search engines. This can help potential clients and partners find you when searching for supply chain services.

- Analytics and Insights: Strikingly provides analytics tools to track your website's performance. This data can help you understand user behavior, which pages are popular, and what needs improvement, aiding in your supply chain management decisions.

- Scalability: Strikingly can accommodate the growth of your supply chain management business. You can add new page features and integrate third-party services or tools.

- Cost-Effective: Strikingly offers different pricing plans, including a free program and affordable premium plans. This flexibility can suit your budget, whether you're just starting or looking to expand your online presence.

- Secure Hosting: Strikingly provides fast and reliable hosting, essential for safeguarding sensitive information often associated with supply chain management.

Ace the World of Ecommerce With Strikingly Websites!

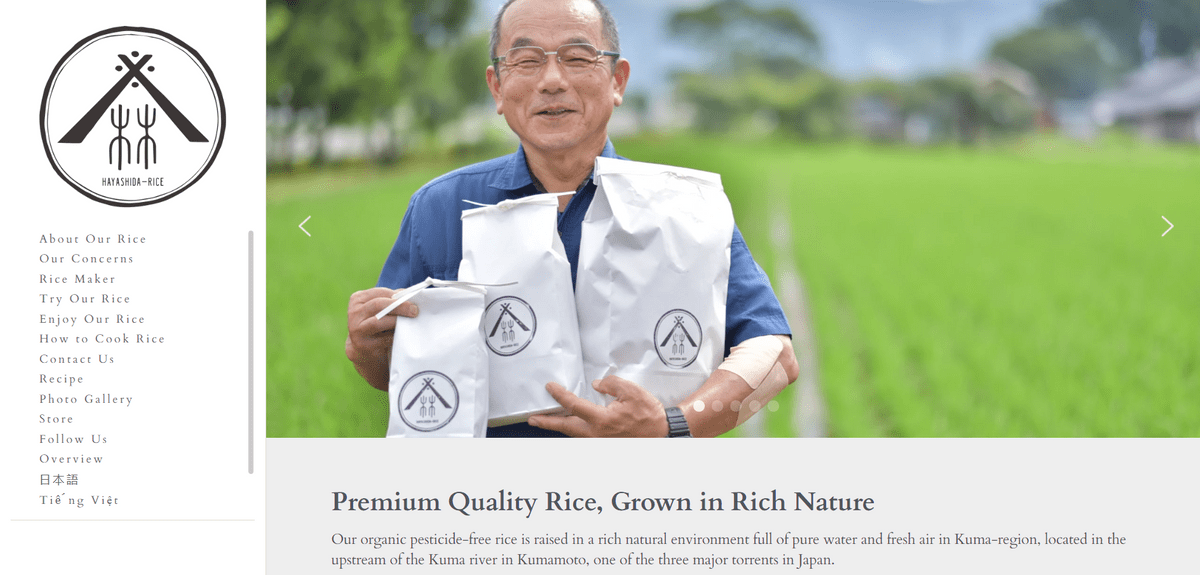

Image taken from Hayashida Rice

Managing supply chain shortages is critical for businesses in today's global marketplace. Proactive steps must be taken to mitigate the impact of these shortages and ensure smooth operations. This includes enhancing supplier relationships, implementing inventory optimization techniques, and adopting agile supply chain strategies.

Collaboration and adaptability play a crucial role in managing supply chain shortages. By working closely with suppliers and partners, businesses can navigate challenges more effectively and find innovative solutions. It is also essential to embrace resilience and remain flexible in unexpected disruptions.

Strikingly, a leading company in the website-building industry has successfully addressed supply chain shortage issues by employing various strategies. They have focused on diversifying their supply chain sources, implementing robust risk management strategies, and leveraging technology and data analytics to forecast and mitigate shortages.

By following best practices like those employed by Strikingly, businesses can overcome supply chain bottlenecks and ensure uninterrupted operations. Learning from these experiences and applying the lessons learned to other industries is essential.

Proactive measures, collaboration, adaptability, resilience, and strategic planning are vital to managing supply chain shortages effectively. By taking these steps, businesses can minimize the impact of shortages on their operations and maintain customer satisfaction.

Want to know more about the world of e-commerce and website building? Chat with us today!